|

Before

Suncoast:

In

Progress (Note the difference between In

Progress (Note the difference between

top 2 railings and older lower Railing):

After Suncoast:

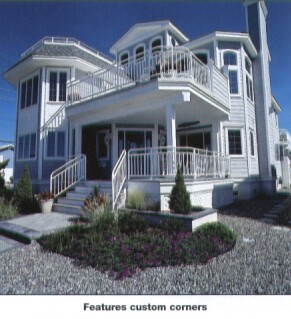

For

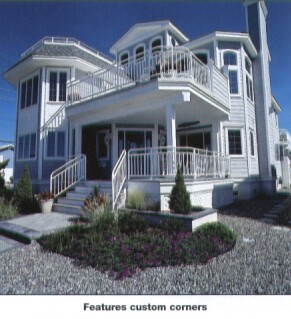

over 12 years Structural Vinyl Railing systems have been chosen to complement, enhance and complete

deck and balcony structures both large and small. For

over 12 years Structural Vinyl Railing systems have been chosen to complement, enhance and complete

deck and balcony structures both large and small.

For beauty and

durability in a vinyl railing product, nothing surpasses Structural

Vinyl Railing.

Complement your

architectural design by specifying Structural Vinyl Railing!

Vinyl

railing was pioneered over a decade ago and continues to break

new ground with convenient knocked down kits.

Designed and packaged to

be easy to order, stock and install, Structural Vinyl Railing continues to set new

standards in railing systems. Structural Vinyl Railing captures the look of custom

fabricated railing with a standard, stock, kit system. Easy to assemble

on the job site, Structural Vinyl Railing enhances any architectural style.

Suncoast MATERIALS

Structural

Vinyl Railing utilizes vinyl that is only virgin PVC: Designed for outdoor

structural applications, all vinyl is of high-grade, exterior weather

resistant compound impregnated with impact modifiers and UV

inhibitors. This proprietary vinyl compound is designed specifically to

withstand the harsh coastal environments. To ensure product performance,

Structural Vinyl Rail does not allow co-extrusion in their manufacturing process,

virtually eliminating visible damage from external sources. Structural

Vinyl Railing utilizes vinyl that is only virgin PVC: Designed for outdoor

structural applications, all vinyl is of high-grade, exterior weather

resistant compound impregnated with impact modifiers and UV

inhibitors. This proprietary vinyl compound is designed specifically to

withstand the harsh coastal environments. To ensure product performance,

Structural Vinyl Rail does not allow co-extrusion in their manufacturing process,

virtually eliminating visible damage from external sources.

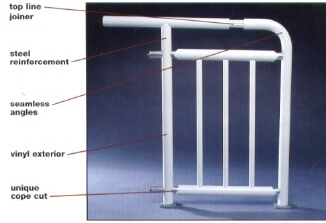

Balusters are designed

to maximize visibility and measure 1" outside diameter with 3/16" wall.

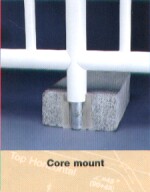

All vertical posts,

horizontal rails and top rails have a 2" outside diameter with a 5/16"

wall. Additionally, core posts inherit the strength of 1" schedule 80

galvanized steel tubing and a 2-1/2" -4" core tail that protrudes from

the vinyl for core mounting applications.

Vertical flange posts

also have 1" schedule 80 steel tubing which is welded to a 3/8" x 3" x

3" steel flange plate. This plate is conveniently pre-punched for

4,3/8" diameter lags and center punched for drainage. Finally it is

hot-dipped and heavy galvanized to completely protect all surfaces and

welds.

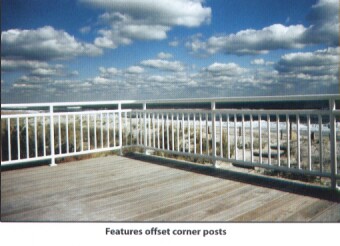

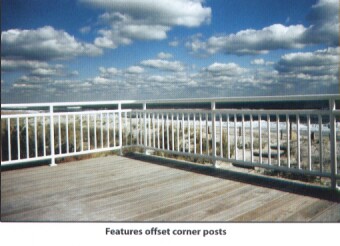

Maximum post spacing is

5'from centerline to centerline and maximum spacing between members is

4", based on code compliant testing data. Posts were designed with

gentle radius 45° & 90° corners and have offset posts in each direction.

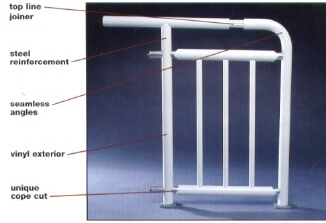

For strength that

exceeds code compliance, top line horizontal rails boasts 1" schedule 40

galvanized steel tubing. Middle and bottom line horizontal railing have

a 2" outside diameter with no internal stiffeners. Maximum continuous

uninterrupted run is 50-75 lineal feet. This dimension allows for

expansion and contraction which varies with environment. For strength that

exceeds code compliance, top line horizontal rails boasts 1" schedule 40

galvanized steel tubing. Middle and bottom line horizontal railing have

a 2" outside diameter with no internal stiffeners. Maximum continuous

uninterrupted run is 50-75 lineal feet. This dimension allows for

expansion and contraction which varies with environment.

|

|

"THE SMARTEST DESIGN

CHOICE YOU CAN MAKE"

POST MOUNTING TYPES

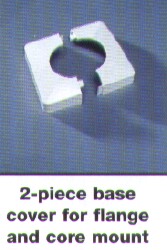

Flange Mount (standard or angled):

Structural Vinyl Railing posts can be easily and

securely bolted to the deck surface using 4, 3/8" bolts, galvanized lag

or through bolts. The decision of bolt style to be utilized should be

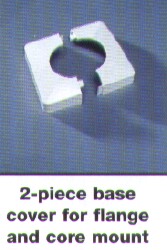

driven by the needs of the application. For esthetic purposes, 2-piece

Flange Mount base covers are available. Flange Mount (standard or angled):

Structural Vinyl Railing posts can be easily and

securely bolted to the deck surface using 4, 3/8" bolts, galvanized lag

or through bolts. The decision of bolt style to be utilized should be

driven by the needs of the application. For esthetic purposes, 2-piece

Flange Mount base covers are available.

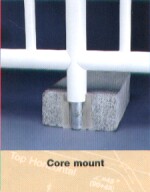

Core Mount:

To create the most secure guardrail, install

Structural Vinyl Railing's

core mount posts. A 3" diameter x 2-1/2" - 4" deep core hole is required

when setting in non-shrink hydraulic cement, which is the recommended

method. Core Mount:

To create the most secure guardrail, install

Structural Vinyl Railing's

core mount posts. A 3" diameter x 2-1/2" - 4" deep core hole is required

when setting in non-shrink hydraulic cement, which is the recommended

method.

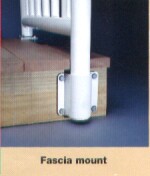

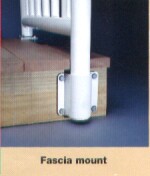

Fascia Mount: When a project requires the deck surface to remain clear,

utilize Structural Vinyl Railing's fascia mount posts. When using this method, the

vinyl covered steel stiffener will extend past the deck surface and

vinyl capped on the bottom. The post can be bored and through-bolted to

the surface of the decking or white, powder coated aluminum brackets can

be used. Fascia Mount: When a project requires the deck surface to remain clear,

utilize Structural Vinyl Railing's fascia mount posts. When using this method, the

vinyl covered steel stiffener will extend past the deck surface and

vinyl capped on the bottom. The post can be bored and through-bolted to

the surface of the decking or white, powder coated aluminum brackets can

be used.

Wall Mount:

When an end wall is available,

Structural Vinyl Railing's system can be

wall mounted using mini-flanges with covers. Wall Mount:

When an end wall is available,

Structural Vinyl Railing's system can be

wall mounted using mini-flanges with covers.

HEIGHTS, CONFIGURATIONS & APPLICATIONS

Standard residential height is 36" while standard commercial is 42".

Standard configuration is level rail. All other configurations require

custom fabricated components that are available through the Structural

Vinyl Railing network of

regional fabricators, located throughout the U.S.A.

Specially designed for use in installations where railing

strength is especially critical: Multi-unit residential apartments,

hotels, motels, condominiums, amusement parks, boardwalks, custom homes,

water treatment facilities, food processing facilities, pools,

commercial properties, municipal properties, parks and recreation

facilities and more.

Structural

Vinyl Railing is code compliant and independent test results are available.

Structural Vinyl Railing carries BOCA-mandated strength and is ADA-compliant for

retrofits. ADA compliance for 1-1/2" diameter handrail has been granted.

Continuous Handrails can be easily fabricated onsite-from the top of the

guardrail then up or down the staircase without a break. Structural

Vinyl Railing is code compliant and independent test results are available.

Structural Vinyl Railing carries BOCA-mandated strength and is ADA-compliant for

retrofits. ADA compliance for 1-1/2" diameter handrail has been granted.

Continuous Handrails can be easily fabricated onsite-from the top of the

guardrail then up or down the staircase without a break.

Additionally Structural Vinyl Railing is non-conductive and fire-retardant for safety

applications.

Technical

Specifications

Design Friendly

Clean

lines and bright white gloss finish complements any design

High

curb appeal

Smooth

finish-no fasteners, clips, screws or rivets

Clean

lines-no welds to snag

Seamless

angles

Gentle

45° and 90° radius corners are standard stock

Custom

work (components) available

Code Compliant

42"

Structural Vinyl Railing is BOCA-mandated strength

ADA-compliant

retrofits easily accommodated

ADA

compliant 1-1/2" diameter handrail can be easily fabricated on site as

continuous handrail-from the top of guard rail, up or down stairs

without a break.

Non-conductive

for safety applications

Fire-retardant

Testing

data available upon request

Exceptional Value

Very affordable, more durable than powder coated

aluminum or stainless steel-with no corrosion or maintenance.

Simple installation

Quick, easy delivery

Technical assistance just a phone call away

Built To Last

Designed for harsh

environments, resistant to salt air

5/16" wall thickness

for strength and durability

Designed to create

confidence

Top line joiners

ensure strong connections at every joint

Thick, strong walls

permit a variety of configurations

Nicks, scuffs or cuts

disappear with sanding, buffing and polishing the

damaged surface (similar to solid surface materials)

Galvanized

Steel Interior

Extremely rigid, ideal for high-rise construction

Strong and sturdy even over long spans

Minimal contraction and expansion

Allows for numerous types of mounts

Vinyl Exterior

Maintenance-free with lifetime warranty

Never

needs painting

Minimal

visible seams

Unique

cope cut on horizontals means graceful curvilinear design

Warm

and friendly to the touch versus steel or aluminum

Suncoast prides itself on

its field-trained staff and over a decade of experience. Customer

service and technical assistance is always just a phone call away! Suncoast prides itself on

its field-trained staff and over a decade of experience. Customer

service and technical assistance is always just a phone call away!

|

For

over 12 years Structural Vinyl Railing systems have been chosen to complement, enhance and complete

deck and balcony structures both large and small.

For

over 12 years Structural Vinyl Railing systems have been chosen to complement, enhance and complete

deck and balcony structures both large and small. Structural

Vinyl Railing utilizes vinyl that is only virgin PVC: Designed for outdoor

structural applications, all vinyl is of high-grade, exterior weather

resistant compound impregnated with impact modifiers and UV

inhibitors. This proprietary vinyl compound is designed specifically to

withstand the harsh coastal environments. To ensure product performance,

Structural Vinyl Rail does not allow co-extrusion in their manufacturing process,

virtually eliminating visible damage from external sources.

Structural

Vinyl Railing utilizes vinyl that is only virgin PVC: Designed for outdoor

structural applications, all vinyl is of high-grade, exterior weather

resistant compound impregnated with impact modifiers and UV

inhibitors. This proprietary vinyl compound is designed specifically to

withstand the harsh coastal environments. To ensure product performance,

Structural Vinyl Rail does not allow co-extrusion in their manufacturing process,

virtually eliminating visible damage from external sources.

Fascia Mount:

Fascia Mount: Wall Mount:

Wall Mount:

Structural

Vinyl Railing is code compliant and independent test results are available.

Structural Vinyl Railing carries BOCA-mandated strength and is ADA-compliant for

retrofits. ADA compliance for 1-1/2" diameter handrail has been granted.

Continuous Handrails can be easily fabricated onsite-from the top of the

guardrail then up or down the staircase without a break.

Structural

Vinyl Railing is code compliant and independent test results are available.

Structural Vinyl Railing carries BOCA-mandated strength and is ADA-compliant for

retrofits. ADA compliance for 1-1/2" diameter handrail has been granted.

Continuous Handrails can be easily fabricated onsite-from the top of the

guardrail then up or down the staircase without a break.